Wire Mesh Cable Tray

EASYCONNECT Wire Mesh Cable Tray

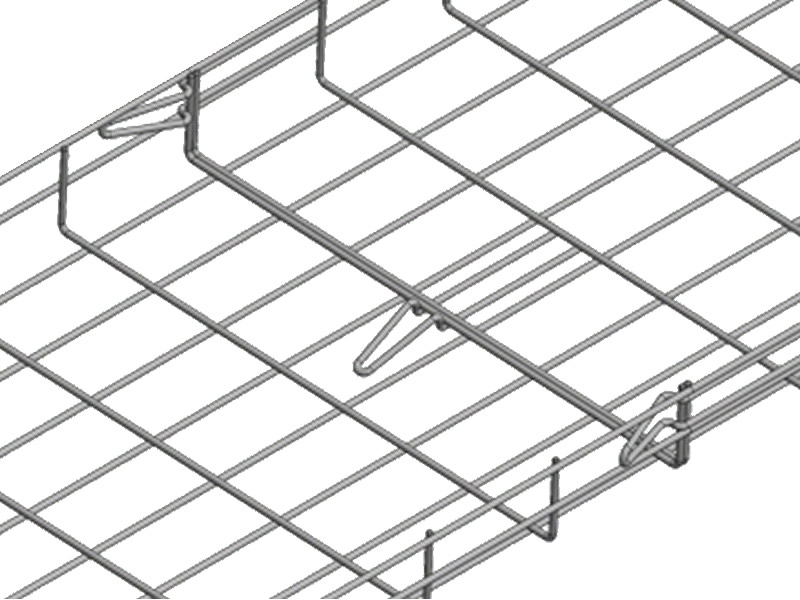

Husky wire mesh cable tray can be used for most wiring situations, however it is best suited for data communications, control and signal cables. The mesh grid system provides cable support while allowing good ventilation of the cables and ease of securing the cables with cable ties. The mesh has a 2" X 4" wire grid system with a safety edge eliminating sharp edges and the possibility of damaging cables or personnel. Wire basket speeds up shipping and eliminates the worry of not having a fitting when you need it. Straight sections are supplied with integral EASYCONNECT connectors on the sides and bottom. The sections with EASYCONNECT connectors are UL classified as suitable for use as an EGC. Unlike conventional tray that uses manufactured fittings for bends, with wire basket the bends and transitions are fabricated in the field from straight sections using inexpensive splice connectors. The EASYCONNECT integrated coupling system is patented under US 2017/0271855 WO 2015/181421.

- Husky wire basket tray is offered in 2", 4", 6", 8", 12", 18", 24", 30" and 36" wide.

- Husky basket is available in 2", 4" and 6" deep.

- Basket trays are offered in 118-1/8 in (3m) length.

- Carbon Steel Wire ISO 16120-2 > Class C9D

- Zinc trivalent bichromium plating according to ISO 2081:2018 with Atotec Corrotriblue Extreme trivalent chromium passivation (Cr3+) according to UNE 112050 and ISO 4520. Subjected to a salt spray test for a minimum of 96 hours.

- Safe working load is established by testing in accordance with NEMA VE-1.

MP Husky EASYCONNECT Wire Basket Tray

MP Husky EASYCONNECT Wire Basket Tray

MP Husky’s wire basket (wire mesh) cable tray systems provide ventilated, flexible support for data, control, instrumentation, and signal cabling in commercial and industrial installations. While suitable for many wiring situations, the mesh tray is especially appropriate for data communications, control, and signal cable applications.

Why Choose Wire Basket Tray?

- Ventilated cable support: The mesh grid design allows excellent air flow around cables — minimizing heat build-up and promoting cable longevity.

- Flexible installation & easy field modifications: Straight sections ship with patented EASYCONNECT side and bottom connectors; bends and transitions are fabricated in the field using splice connectors — no need for pre-manufactured fittings.

- Safer handling: The tray features a formed safety edge to eliminate sharp edges and reduce the risk of cable damage or injury during handling and installation.

- UL-classified grounding: Straight sections with EASYCONNECT® connectors are UL-classified as suitable for use as an equipment grounding conductor (EGC).

Typical Applications

The wire basket tray is ideal for:

- Data centers, server rooms, and network closets

- Instrumentation and control circuits in industrial facilities

- Retrofits or expansions where cable routing changes are expected

- Projects where ventilation and cable tie-based bundling are preferred over rigid conduit or solid-bottom trays

Construction & Materials Overview

Husky wire basket trays are constructed using carbon-steel wire meeting ISO 16120-2 (Class C9D). Sections are supplied with integral EASYCONNECT® splice connectors on sides and bottom, enabling secure but flexible assembly.

The mesh grid is approximately 2" × 4" (50 mm × 100 mm) and includes a formed safety-edge perimeter. Standard straight sections are 118-1/8 in (3 m) long. Tray widths vary from 2 in up to 36 in; typical depths are 2, 4, or 6 in. Finish is the original zinc-trivalent-bichromium plating (Atotec Corrotriblue Extreme, Cr³⁺), tested to at least a 96-hour salt spray resistance.

Engineering Data & Safety Factors

Engineering Data & Safety Factors

MP Husky publishes load tables for EASYCONNECT wire basket tray that are tested in accordance with NEMA VE-1. These tables use a 1.5 safety factor and an 8 ft (2.44 m) support span as the basis for the published safe working load.

If your project or local standards require a 2.0 safety factor, you can quickly convert the catalog value:

-

Start with the catalog safe working load (SWL) based on a 1.5 safety factor.

-

Multiply that value by 0.75 to get the equivalent SWL at a 2.0 safety factor.

For example, a tray with a published SWL of 32 lb/ft at 1.5 safety factor would be rated at 24 lb/ft when evaluated with a 2.0 safety factor.

Cable Fill Guidelines (50% Fill)

Cable Fill Guidelines (50% Fill)

To simplify design, MP Husky provides a 50% cable fill chart for wire basket tray. The chart shows how many round cables of various outside diameters can be installed in each tray size at half the cross-sectional fill.

A few typical examples from the 50% fill data:

-

A 2" deep × 12" wide tray can accommodate roughly:

-

~335 small-diameter (0.21") data cables, or

-

~164 larger (0.30") cables at 50% fill.

-

-

A 4" deep × 24" wide tray can handle approximately:

-

~1,342 0.21" cables, or

-

~657 0.354" cables at 50% fill.

-

-

A 6" deep × 24" wide tray supports on the order of:

-

~2,013 0.21" cables, or

-

~986 0.30" cables at 50% fill.

-

These values are intended as quick selection guidance. Final cable counts should always consider:

-

Applicable electrical codes and standards

-

Cable manufacturer installation recommendations

-

Required derating for bundling and ambient temperature

Support Spacing, Design Loading & Deflection

Support Spacing, Design Loading & Deflection

To control deflection and maintain proper performance, MP Husky provides simple guidelines for support placement on wire basket systems:

-

Maximum support span: 8 ft (2.4 m) between supports.

-

Avoid supports directly under splices: Do not place a support directly beneath the splice between two tray sections.

-

Locate splices near the quarter point: The splice between adjacent sections should be positioned approximately at the L/4 point between supports (no further than a quarter of the span from the nearest support).

These practices help keep deflection within acceptable limits, improve load distribution, and maintain the integrity of the EASYCONNECT splice.

Powder-Coated Finish Options

Powder-Coated Finish Options

In addition to the standard electroplated zinc finish, wire basket tray is available with a powder-coated finish. Powder-coated items are identified by adding “PC” to the product number, followed by a one- or two-letter color code.

Example naming structure (for illustration):WBS24-4-3M-EZ-PCB → 4" deep × 4" wide tray, electroplated zinc base, powder-coated black.

Typical standard powder-coat colors and their codes include:

-

Black (B)

-

Blue (BU)

-

Red (R)

-

Orange (O)

-

White (W)

-

Green (G)

-

Gray (GY)

-

Yellow (Y)

-

Purple (P)

-

Brown (BR)

-

Primer (PR)

In addition to the standard color codes (B, BU, R, O, W, G, GY, Y, P, BR, PR), custom powder-coat colors are available upon request. MP Husky recommends contacting the factory for special color requirements or for environments that need additional corrosion protection beyond the standard electroplated zinc finish.

Basket Profiles (2", 4" & 6" High)

Basket Profiles (2", 4" & 6" High)

The catalog shows detailed cross-section profiles for the three standard basket depths: 2", 4" and 6". In each case, the sidewall and bottom wires are arranged on approximately 2" (50 mm) centers, providing uniform support for cabling and predictable loading behavior.

Key profile characteristics:

-

2" high profiles

-

Available in widths from 2" up to 24".

-

Compact profile ideal for shallow installations, tight headroom, and smaller bundles.

-

-

4" high profiles

-

Widths from 4" up to 24".

-

Most commonly specified depth, balancing capacity and vertical space.

-

-

6" high profiles

-

Widths from 8" to 36".

-

Deep sidewalls for higher cable capacity or larger bundle diameters.

-

Load Capacity Summary by Tray Depth

Load Capacity Summary by Tray Depth

The Profiles & Loading section of the catalog provides detailed safe working loads (SWL) for each tray size, all based on an 8 ft (2.44 m) support span and a 1.5 safety factor, with standard electroplated zinc finish.

A high-level overview for EASYCONNECT wire basket tray:

2" High Trays (Series WBS22)

-

Widths from 2" to 24".

-

SWL values at 8 ft span range roughly from 11 lb/ft up to about 33 lb/ft, depending on tray width.

-

Narrower widths are not UL-classified as equipment grounding conductors; some wider widths are EGC-classified, while others remain “N/A” due to limited cross-sectional area.

4" High Trays (Series WBS24)

-

Widths from 4" to 24".

-

SWL values at 8 ft span range from approximately 14 lb/ft to 40 lb/ft.

-

Wider 4"-deep trays (8" and above) are UL-classified as equipment grounding conductors; the load table notes any items that remain non-EGC due to cross-section area.

6" High Trays (Series WBS26)

-

Widths from 8" to 36".

-

SWL values at 8 ft span range from about 31 lb/ft (6" × 8") up to around 77 lb/ft (6" × 36").

-

All listed 6"-deep trays are designed as higher-capacity options for larger cable bundles and heavier loads.

Each catalog entry also identifies:

-

Required bottom splices for wider trays

-

Whether the part is UL-classified as an equipment grounding conductor (EGC)

Wire Mesh Cable Tray FAQs

-

What cables are best suited for wire mesh tray?

Answer: Data, communication, control, and signal cables — especially where good ventilation, open access, and ease of securing cables with ties are needed. -

What sizes are available for EASYCONNECT wire mesh trays?

Answer: Widths: 2", 4", 6", 8", 12", 18", 24", 30", 36"; Depths: 2", 4", 6"; Length: 118-1/8" (3 m). -

What material and finish does MP Husky use for wire mesh trays?

Answer: Carbon steel wire, with zinc trivalent bichromium plating (Atotec Corrotriblue Extreme Cr3+), meeting ISO 2081:2018 / UN E standard; trays are tested for a minimum 96-hour salt spray corrosion resistance. -

Can mesh trays support heavy or power cables?

Answer: Typically they are intended for light communications/control cables; heavy power cables usually require ladder, solid-bottom or other tray types per load/span and code requirements.