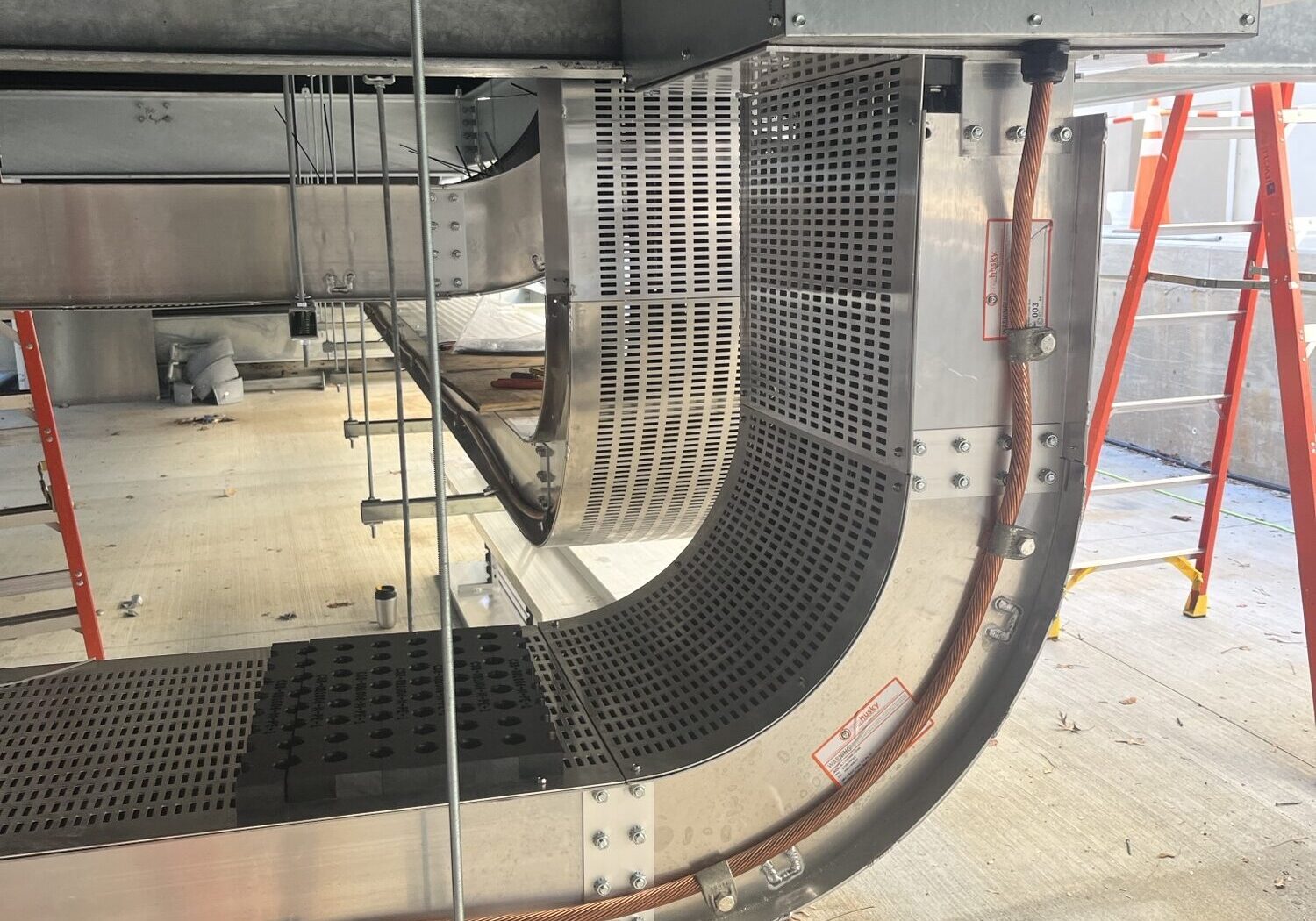

Cable Bus

MP Husky Cable Bus Systems

For over 70 years, MP Husky Cable Bus Systems have been engineered and manufactured for superior reliability. MP Husky is the largest and most experienced Cable Bus manufacturer in the industry. We utilize less constructive material to provide significant savings versus non-segregated phase duct, conduit and wire, and other electrical feeders. As copper prices have continued to remain at historically high levels, the savings clients realize are even greater and more important. No matter how you look at it, MP Husky Cable Bus outperforms other electrical busways in reliability, cost, and flexibility. See for yourself why more owners, engineers, and buyers choose MP Husky Cable Bus systems over the competition

Cable Bus Manufacturers Superior Reliability

70 years of engineering, design and manufacturing of Cable Bus systems with installations in nearly every environment, MP Husky Cable Bus Systems are proven and tested to be the most reliable system on the market.

Five key features contributing to superior reliability:

- High quality cables are continuous from termination to termination, eliminating faulty splices.

- MP Husky Cable Bus utilizes factory insulated conductors that are designed and manufactured to withstand the harshest outdoor environments. Since our system design is not affected by moisture and is ventilated for indoor and outdoor applications, it does not require heater strips, filter breathers, and thermostats that competitive technologies require, leaving less parts to fail.

- Each system’s phasing arrangement is verified by computer generated inductive reactance calculations to ensure optimal load balance.

- The system’s short circuit capacity is tested to over 100,000 RMS sym. amps. Engineered polymer support blocks provide maximum performance and will not decay, rot or lose structural integrity from exposure to weather, unlike wood or fiberglass.

- Top and bottom covers are ventilated for optimum cooling of conductors to achieve a free air rating. Actual Heat Rise Tests prove system design.

Cable Bus Lowest Cost

In most electrical applications over 1,000 amps, Cable Bus costs significantly less than non-segregated bus duct cable in tray or conduit and wire systems. As ampacity and/or the cost of copper increases the cost savings of Cable Bus over other systems is even greater.

Since Cable Bus is continuous there are no power losses from intermediate splices or connections. Cable Bus has a lower impedance and lower voltage drop because its conductors are properly phased. Spaced and secured in a pre-engineered system. This reduces operating cost by conductors, combined with our free air rating, allows you to operate fully and efficiently with less conductor than would be called for with other types of systems.

Cable Bus Unmatched Flexibility

MP Husky Cable Bus is easily adjusted to accommodate misplaced equipment and unforeseen obstacles during construction, with little or no delay in the project. Where-as rigid non-segregated phase bus duct must be exact to make equipment terminations, MP Husky provides additional cable and Cable Bus housing to accommodate changes that often occur in the field. If the placement of equipment requires a different bus length, supplemental Cable Bus sections can be quickly adjusted in the field to the required length.

Cable Bus FAQs

-

What is cable bus and how does it differ from bus duct or conduit?

Answer: Cable bus uses continuous insulated conductors within ventilated housing, while bus duct uses rigid bus bars or non-segregated conductors; conduit uses individual cables. Cable bus reduces impedance, avoids splices, and provides flexibility for field modifications. -

When is cable bus the preferred choice?

Answer: For high-current applications (e.g. >1,000 A), long feeder runs, outdoor or harsh-environment installations, or where flexibility during installation is needed. -

Is MP Husky Cable Bus compliant with NEMA / UL / CSA standards?

Answer: Yes — MP Husky manufactures per applicable UL and CSA standards for cable bus and cable tray systems (see certifications page). -

What are the key benefits of using MP Husky Cable Bus vs traditional wiring?

Answer: Lower cost (especially as copper prices rise), reduced power losses, lower impedance, continuous conductors (no splices), ventilated housing (better cooling), and simplified installation/flexibility.