Cable Bus

Reliable

- Our system utilized continuous runs of power cable (no faulty splices) from termination to termination.

- MP Husky utilizes high quality, factory tested cables.

- Polymer cable support blocks will not decay, rot or lose structural integrity for 50+ years.

Cable Bus

Lowest Cost

- Free Air Rating allows greater ampacity with less conductors, achieving significant cost savings.

- Substantial savings on materials and installation costs compared to other systems.

- In addition to utilizing the least amount of space reduced fittings provide easier, more cost effective and precise connections.

Cable Bus

Flexible & Adaptable

- Unlike non-segregated bus duct, MP Husky Cable Bus systems are easily adjusted in the field to accommodate misplaced equipment that often occurs during construction.

- Easily routed around unforeseen field obstructions (i.e. piping, structural steel, equipment, etc.)

- Our extensive custom fabrication capabilities ensure that we can manufacture a system to meet all your difficult coordination challenges.

Cable Bus

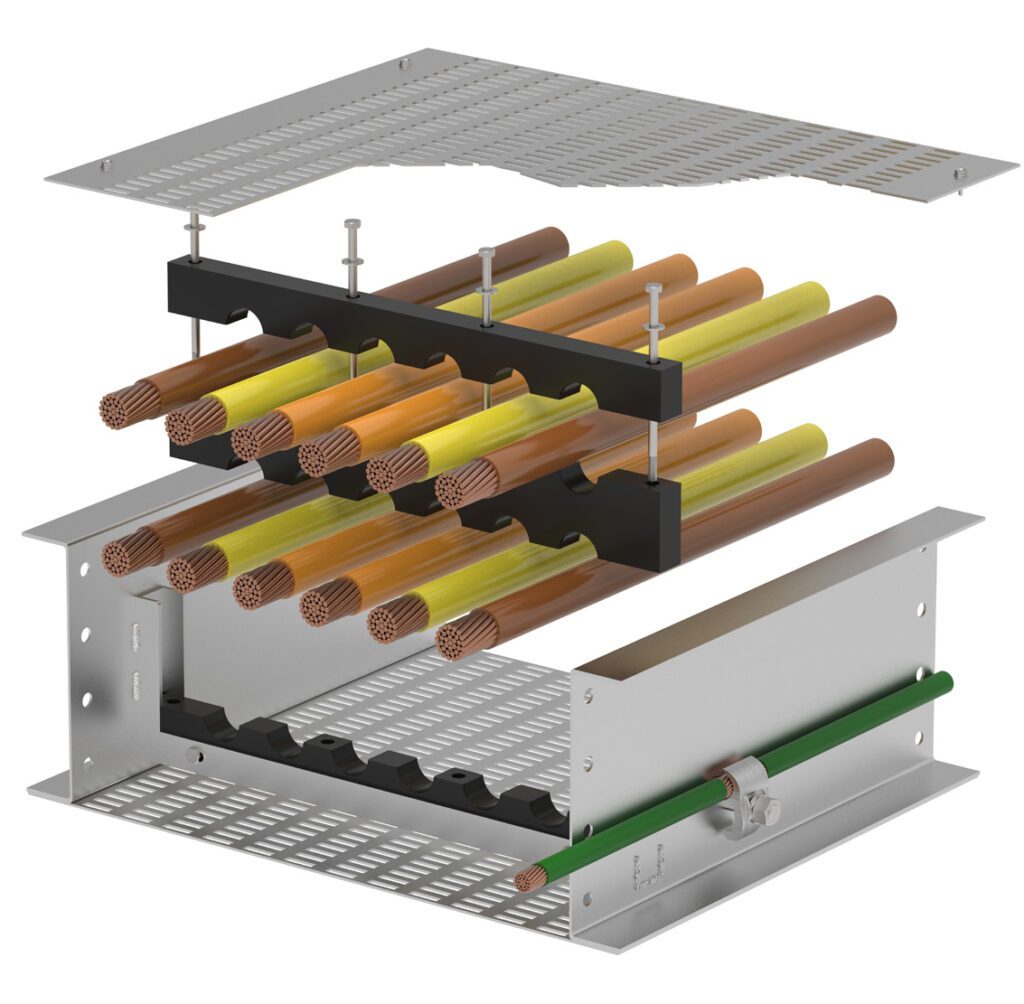

Free Air Rating for Conductors

- Up to 40% less conductors are needed to carry fully rated current.

- Minimum temperature rise due to ventilated enclosure and maintained cable spacing by custom support blocks.

- Maximum ampacity in accordance with ICEA listings for 90 degree Celsius rated conductors.

Cable Bus

Indoor or Outdoor Applications

- Utilized for indoor or outdoor applications.

- No special finishes are required with housing utilizing non-corrosive marine grade aluminum.

- Excellent protection against adverse environments including Paper Mills, Fossils, Chemical Plants, Cold, hot and Tropical locations.

- Suitable for food processing and data centers as well.

Cable Bus

Labor Savings

- Cables run in parallel throughout entire bus housing.

- Our system does not interleave or transpose cables in the bus housing.

- Lightweight, ventilated enclosure that two people can easily lift 12’ or 24’ sections into position.

- No special heavy erection equipment required.

Cable Bus

Safety

- MP Husky Cable Bus is an all welded rigid construction.

- Contractors are free of shock hazards - no exposed buselements, only insulated conductors used.

- Ventilated design prevents entry of foreign objects.

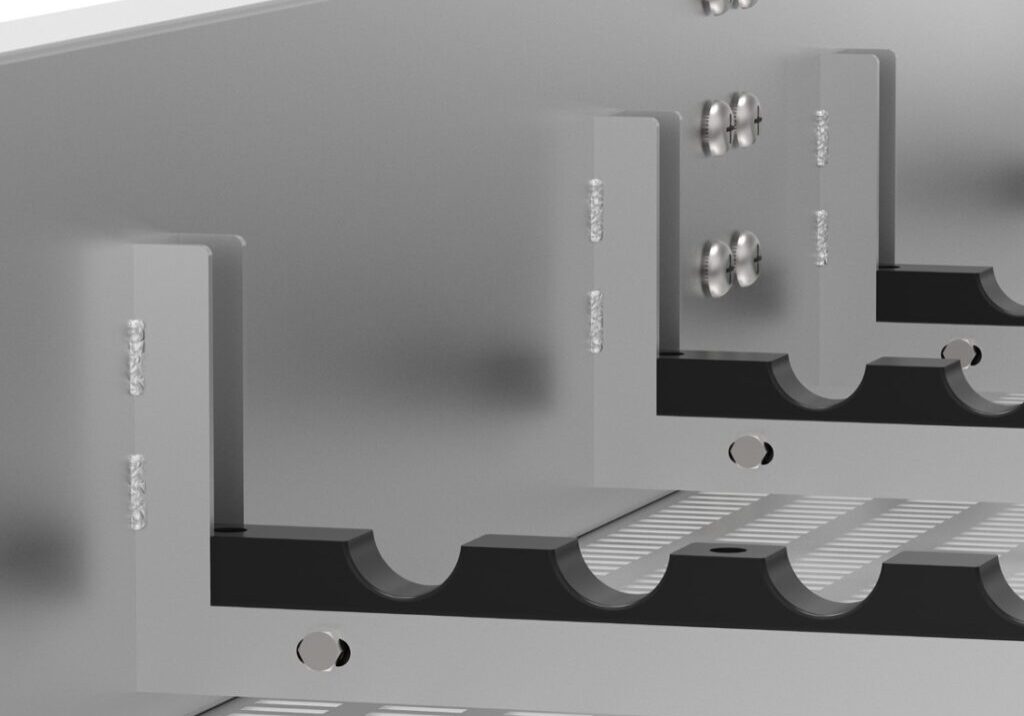

- Support block design assures proper cable support and complete restraint during short circuit conditions.

Cable Bus

Less Support Material

- Design criteria accomplishes high load carrying ability on long spans with minimal support material

- Flush bottom design allows for use of standard support material.

Cable Bus

Proper Phase Balance

- MP Husky utilizes an Inductive Reactance Program to achieve the proper cable spacing and phasing arrangement that ensures low impedance and low voltage drop.

- Balanced load carrying of conductors prevents over-heating of cables.

- Cable support blocks provide continuous maintained spacing.

Cable Bus

Testing and Certification

- Certified to CSA/ANSI 22.2 #273:19 (Cablebus).

- UL Classified as an equipment ground.

- Actual Heat Rise Tests on widest range of system ratings.

- Actual Short Circuit Test up to 120kA RMS Symmetrical.

- Actual Heat Rise Test verifying MP Husky Cable Bus in trench applications.

- Actual Load Tests confirm structural capability of housing, including up to 20’-0” spans.

Cable Bus

Match-Marked Layout Drawings

- Cable Bus system layout drawings are shipped complete with match-marked numbers that correspond to each Cable Bus section.

- Product labels utilize large items numbers to facilitate quick product location and installation.

Cable Bus

Vertical Bracing System

- Stainless Steel bolts not required during installation.

- Makes vertical and horizontal pulls easier, Thus reducing labor Costs.

Cable Bus

Factory Fabricated - All Welded

- Bottom cable support block is factory pre-installed in Cable Bus Housing.

- Entire system is factory fabricated to fit the specific requirements of each individual project.

- All welded constructed for maximum strength.

- All welders are AWS Certified.

Cable Bus

Engineering Services

- Experienced all knowledgeable engineering group that can handle difficult coordination challenges.

- Engineering support prior to and during engineering and construction, as well as during and after start-up.

Cable Bus

Complete System

- MP Husky Cable Bus systems are complete with all necessary fittings for direction and elevation changes.

- Termination boxes, equipment flanges, firestops, and wall seals.

- Lugs and termination kits for MV systems.